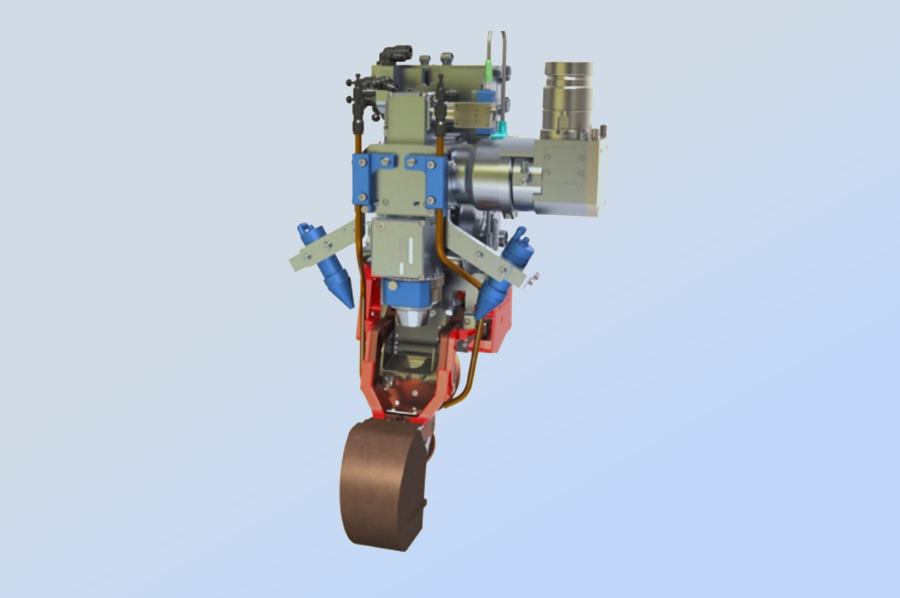

WT04-STDW

WT04, a multi-function laser fusion welding tool, integrates flexible fixture with single or double pressure roller, high-precision optical seam tracing system, and MFU auto-zooming module. This tool could be applied in various process field such as BIW roof welding, door welding, tailgate welding, etc. It has been widely endorsed by lots of clients such as VOLVO, GEELY, VW Poland, etc., due to the continuous and smooth welding seam without any necessity of post-treatment.

ØST (high-precision optical seam tracking system): could compensate the deviation (±2.5mm) during welding process independently from robot

ØMFU (auto-zooming module): could realize zooming automatically (-6~20mm) without changing laser spot diameter

ØSingle/double pressure roller system: could substitute traditional welding fixture, fulfill multi-car model manufacturing in single line, and be suitable for various joint types such as fillet welding, overlap welding, etc

Type | WT04-YDSW-1.0 |

Wavelength | 900-1100 nm,suitable for different type of solid-state laser source |

Maximum power | 10 kW(BPP=8) |

Focusing distance | 200 mm,250 mm,300 mm,400 mm,500 mm |

Collimating distance | 160 mm,180 mm,200 mm |

Optical fiber diameter | 200 um /600 um |

Optical fiber coupler type | QBH,LLK-D |

Pressure roller diameter | 110 mm |

Seam tracking accuracy | 0.05 mm |

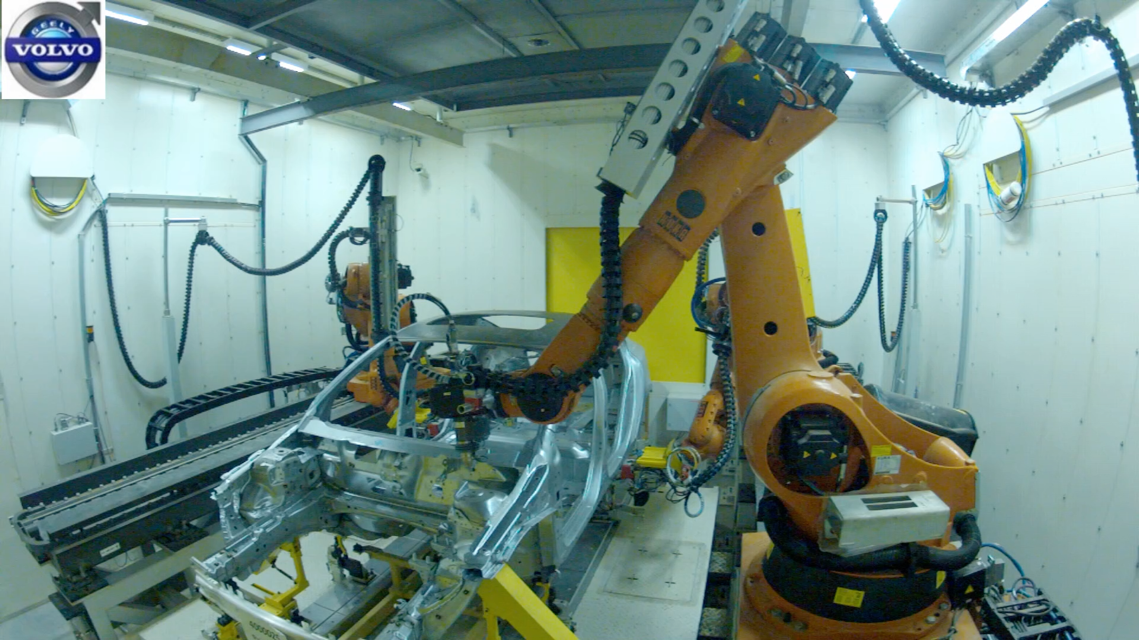

Laser welding of BIW in Volvo .

Application location: Daqing Volvo, Chengdu Volvo, Volvo China Taizhou Luqiao Branch.

Laser welding of BIW in Geely

Application location: Geely Car Research Institute, Zhangjiakou Geely, Hangzhou Bay Geely, Yuyao Geely, Chengdu Geely, Xi’an Geely, Changxing Geely.